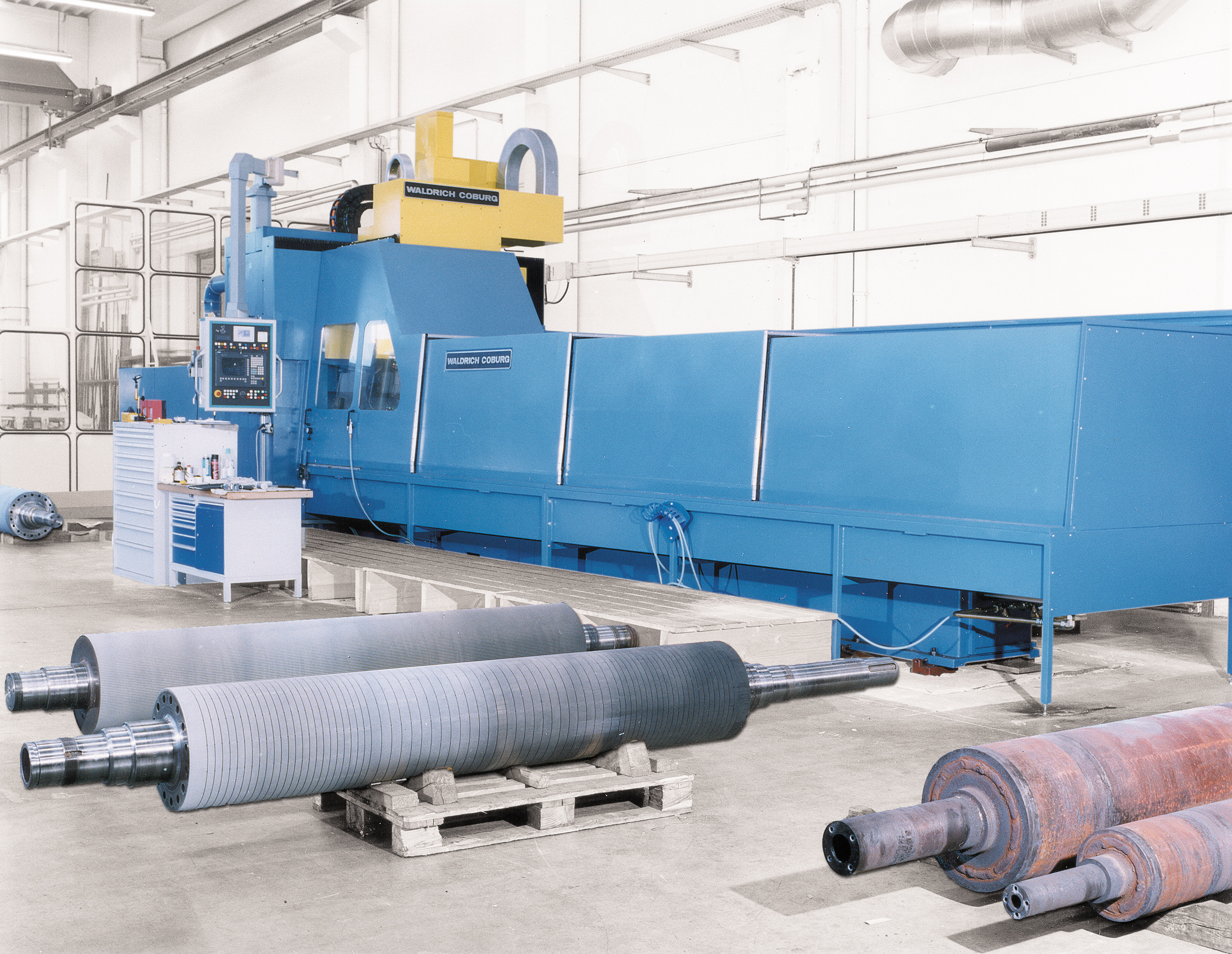

Precision Grinding Machines

WALDRICH COBURG'S lineup of precision surface grinders is renowned worldwide for accuracy, with an array of standard features to ensure dependable performance. All three models incorporate portal-type construction, hydrodynamic guideways, and a double-V bedway system for consistent results while holding extremely tight tolerances. Our precision grinding machines can be equipped with either a fixed vertical wheel for defined tasks or universal grinding wheels for multi-axis control, with automatic grinding wheel changers to increase spindle uptime and productivity.

Precision surface grinding machines from WALDRICH COBURG

WayGrind

Sometimes referred to as the “mother machine,” the WayGrind is the birthplace of many of the world’s machine tool components, producing accurately flat surfaces on complicated parts.

RailGrind

The RailGrind linear rail grinder is integral in the manufacture of compact linear guideways for machine construction, equippable with two or three grinding spindles for simultaneous grinding.

CorruGrind

With pinpoint accuracy, the CorruGrind precision grinder produces corrugated rolls used in the manufacture of corrugated cardboard, preventing the tearing and shredding of paper products.

Why choose WALDRICH COBURG for your precision grinding needs?

The WALDRICH COBURG name is synonymous with precision, power, and operational efficiency — big jobs done in less time, with utmost confidence. With a host of automation options for enhanced productivity, sturdy portal construction for rigidity and accuracy, hydrodynamic guideways for vibration damping, and a double V-bedway system to offset the effects of thermal expansion, we take the “precision” in precision grinding very seriously. And as with any of our machine tools, you can be assured of world-class service and support.